Plank Gratings - Anti Skid Safety Walkway Grating

Plank Grating is a kind of anti slip one-piece safety steel grating with raised diamond or dimple design allowing for the drainage of fluids, mud, chips, debris through the floor or treads while retaining anti skidding surface.

We supply galvanized steel plank gratings in a wide variety of standard widths and channel heights, non-standard shapes and sizes also available for construction of non-slippery walkways, safety flooring and stair tread in various industries.

Anti-Skid Plank Grating Safety Treads

Thickness: 2mm, 2.5mm, 3.0mm

Width: 300mm, 500mm, 800mm, 1000mm

Length: 1m, 2m, 2.5m, 3.0m, 3.66m

Height: 20mm, 40mm, 45mm, 50mm

Material: Low carbon steel, Aluminum, Galvanized Steel, Stainless Steel.

Low carbon steel can be electro galvanized and hot dipped galvanized.

Features: Anti-skid, anti-rust and anti-corrosion, uniform hole size, durable, without burs and broken holes, and lightweight design providing high strength-to-weight ratio and virtually maintenance free.

Surface pattern: Raised diamond pattern configuration in metal struts offering slip resistance in all directions of the steel grating.

United Interlock Planking Grating

United Interlock Steel Grating is mainly used for flooring and walkways, mezzanines, stair treads, maintenance walkways and staging platforms, scaffolding planks, mining and quarry tower decking, ventilation covers for tanks and wells, archetectural wall coverings and shelving.

Material: Carbon Steel

Finish: HDG

Surface: Anti-skid, slotted-smooth punched surface and solid unpunched surface.

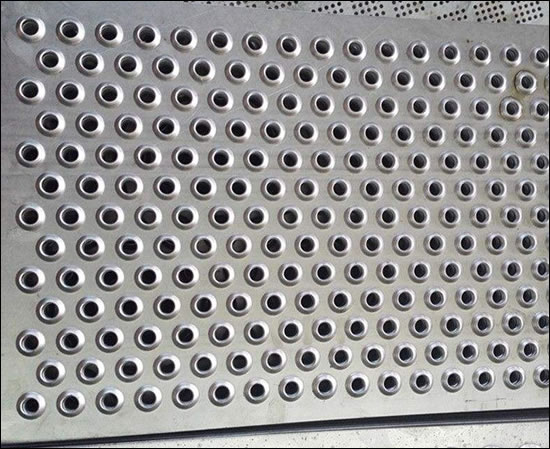

Perforated Plank Grating as Grip Safety Grating, Heavy Galvanized for Corrosion Resistance

Material: Galv. steel, aluminum, ss304, 316.

300*3000mm, 500*3000mm dimple grating cut to size

Grating surface: Embossed dimple

Uses: Grip grating, stair step, channel grating

for tanks, platforms

Process

Die making: Perforating process starts by designing the precision die which is critical for the

quality of the grating product.

Perforating: Advanced CNC machine is used to produce state-of-the-art perforated sheet with a thickness from 0. 4mm to 25mm.

Sheet Shearing: Margins are sheared in strict accordance with tolerance.

Hole shapes

Embossed hole / raised dimple