Channel Grating is a one-piece metal plank grating manufactured by cold forming steel into a channel shape structure offering much higher strength and ductility than traditional cast iron grates. The walking surface has square, diamond or other holes to create a grip surface and to allow for the dissipation of water and debris, suitable for large span and heavy loading sewage system, well covers and gully covers, used in docks, airports, seaports, and various engineering projects. Also called Ditch Grating, U Channel Grating or Gully Grating.

Galvanized channel gratings have following advantages over cast iron:

Hot-dip galvanizing against corrosion, less maintenance needed and easy replacement;

Security design available: box with hinged lid and connection, security, safe, easy to open;

Large span grating cover saving investment using the lowest ratio of iron materials;

Higher strength than cast iron, can be used for terminals, airports and other large span and heavy load environment;

Full specifications, more sizes and shape options provided meeting different environment and loading requirement.

We supply channel steel grating with standard ASTM A 27, 47, 48, 283, JIS G 3101.

We can design and manufacture standard channel grating and special grating in customized shapes per client's requirements.

Grating for Open Channels - Bituminous Painted

Mechanical Pitch : 33 x 33 mm

Load bearing bar size :50*5 mm

Transverse Bar Size :Diameter 5 mm x width of panel

Front Edge Protection :by 30 x 30 mm soltted angle

Protection: All surfaces to be made free from rust & scale by chemical cleaning

Painting: Bituminous painted by dipping dry film 100 micron

Grating size 880 x 1000

Grating size 1250 x 1000 x 50

Ditches Grating and Frame, Galvanized Grating

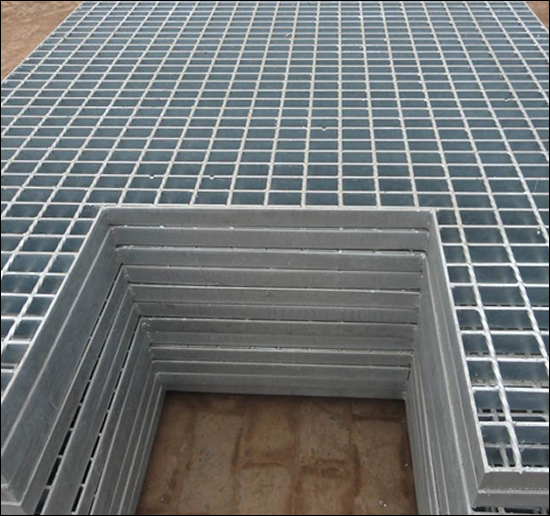

Grating cover for concrete ditch

Material:

Galvanized grating

Mesh 30x30 Plate: 30x3

L edge: 35x35x5t

Light duty grating with anchor hook

Galvanized Grating, Heavy Duty

Mesh 35x35 Plate: 50x5

L60x60x5t

Project illustration- Galvanized channel gratings used in structural marine works:

CONCRETE DITCH WITH GRATING COVER

GRATING COVER

| Frame A mm * mm | Cover C mm * mm | Full Opening W mm * mm | Frame Height E mm * mm | Cover Depth F mm * mm | Remark |

| 681 * 681 | 533 * 533 | 457 * 457 | 69 | 73 | Heavy Duty |

| 607 * 607 | 505 * 505 | 457 * 457 | 48 | 49 | Light Duty |

| 834 * 834 | 686 * 686 | 610 * 610 | 69 | 105 | Heavy Duty |

| 760 * 760 | 630 * 630 | 610 * 610 | 48 | 49 | Light Duty |

| 1138 * 1138 | 990 * 990 | 914 * 914 | 69 | 122 | Heavy Duty |

GALVANISED STEEL GRATING COVER FOR LOAD CLASS ACCORDING TO EN 1433

POLYMER CONCRETE CHANNEL WITH GRATING COVER

CHANNEL GRATING INSTALLATION DETAIL

Ductile Iron Channel Gratings

Super Heavy Duty Ductile Iron Channel

Grating and Frame.

With holes for anchor bolt.

With Holes for jointing.

Material : Spheroidal or nodular iron (also known as

ductile iron) according to BS EN 1563:1997.

Dimensions :

Clear opening 200mm

Over base 510x370mm

Depth 75mm

Design load : Minimum 900 kN (approx. 90 tons)

according to BS EN 124 Class F900.

Protective coating : Black Bitumen coated.

Coal tar epoxy coated (optional)

Heavy Duty Cast Iron Channel Grating

with Holes for anchor bolt.

Bolted frames to form continuous runs.

Material : Spheroidal or nodular iron (also known as ductile iron)

according to BS EN 1563:1997

Dimensions:

Clear opening 400 mm.

Over base 760x570 mm.

Depth 75 mm.

Design load : Minimum 900 kN (approx. 90 tons)

according to BS EN 124 Class F900.

Protective coating : Black Bitumen coated, or

Coal Tar Epoxy (optional)

Super Heavy Duty ductile iron channel grating and

frame.

With holes for anchor bolt.

With holes for jointing.

Frames bolted together to form continuous run.

Material : Spheroidal or Nodular iron (also known as ductile

iron) according to BS EN 1563: 1997.

Dimensions:

Clear opening 300 mm.

Over Base 510x470 mm.

Depth 75 mm.

Design load : Minimum 900kN (approx. 90 tons) according to BS EN

124 Class F900.

Protective coating : Black bitumen paint or Coal-Tar Epoxy (Optional)

Channel Grating Panels for Gully Covering, L Edge Design

Panel sizes:

700 x 1000 mm

1500 x 1500 mm

Designed with L shape edge.

Channel Ditch Grating - Drainage Steel Grates, Lighty Duty

Iron steel grate heavy and light type, suitable for most ditches types

Heavy Duty U Grating Safety Tread Covers, Made of Ductile Iron

Ductile iron gratings in various sizes and designs, with a minimum 900kN loading capacity, suitable for most municipal projects as trench covers, underground channels, ventilation shaft, light wells, and inspection wells.

Size and Shapes of Well Covers Grating: Channel grating and well covers can be made to meet different environment, load, span and shape requirements, and can be customized based on provided size and shape. The well covers can be round or square.

Types:

Diamond channel grating

Round Channel Grating

Dimple Channel Grating

U Channel trench gratings are mainly used for municipal sewage ditches, well covers and drainage covers. Specifications as listed in tables below:

Item |

Description |

Bearing Bar |

25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5, 50x5, 65x5, 75x6, 75x10---100x10mm etc |

Bearing Bar Pitch |

12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc |

Twisted Cross Bar Pitch |

38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2'' & 4'' etc |

Material Grade |

ASTM A36, A1011, A569, Q235, S275JR, SS304, SS400, Mild steel & Low carbon steel, etc |

Surface Treatment |

Black, self colour, hot dip galvanized, painted, spray coating |

Grating Style |

Plain / Smooth, Serrated /teeth, I bar, serrated I bar |

Standard |

China: YB/T 4001.1-2007,USA:ANSI/NAAMM(MBG531-88), |

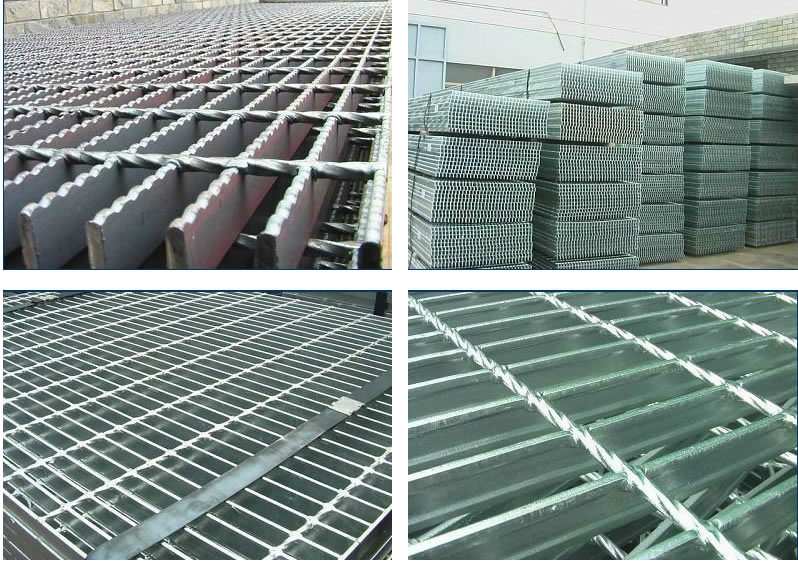

Samples Illustration:

Qindelin Steel Grating Engineering Corporation

Add: New Development Zone, Dezhou, Shandong, China

URL: https://www.steelgrating.org

Email: sale@steelgrating.org