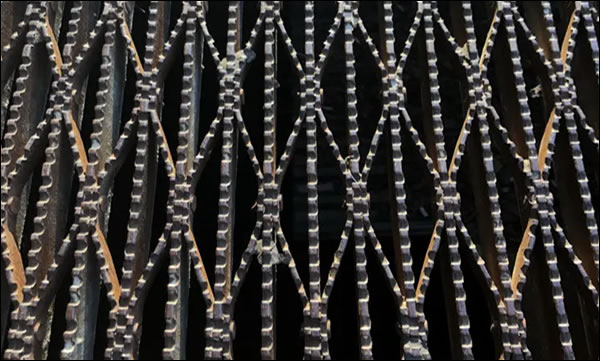

Heavy Duty Riveted Steel Grating Galvanized Low Carbon Steel

Riveted steel grating is a heavy-duty steel bar grating made by riveting bearing bars and cross bars together with sturdy connection. Riveted grating offers superior strength and durability compared to welded or pressure-locked grating, ideal for heavy duty industrial and load-bearing applications.

Uses:

Riveted steel grating is widely used in heavy-duty flooring, loading ramps, walkways and high loading trench covers, mainly:

- Dock Platforms

- Marine Walkways

- Bridge Decking

- Loading Ramps

- Catwalks

- Industrial Platforms

- Drainage Covers

- Mining Walkways

Riveted Grating Common Specification

Bearing Bar Depth: 19mm, 25mm through 44mm, 51mm through 64mm.

Minimum Size of Connecting Bars:

Thickness 3.2mm;

Depth: 16mm, 19mm, 25mm.

Riveted Steel Grating Products

Heavy-Duty Riveted Grating for Platform Decking

Specification: Steel 37-R-5, Grating 53/8 inch

Finish: Hot dipped galvanized

Heavy Duty Riveted Steel Grating

Specification:

2-5/16 inch x 5 inch opening (bearing bar spacing)

Grating used as platform decking

Riveted Grating 1220 x 2440mm

Steel flat size: 25 x 5

Bearing bar pitch 20mm (between bearing bar), 25mm from center to centre of bars.

Cross bar pitch of 100mm

Material:

Untreated, low carbon steel.

Supply to UK.

Rivet Steel Grate

Specification:

29mm x 178mm opening

Bearing bar spaced 29mm between faces rivets spaced 178mm on center

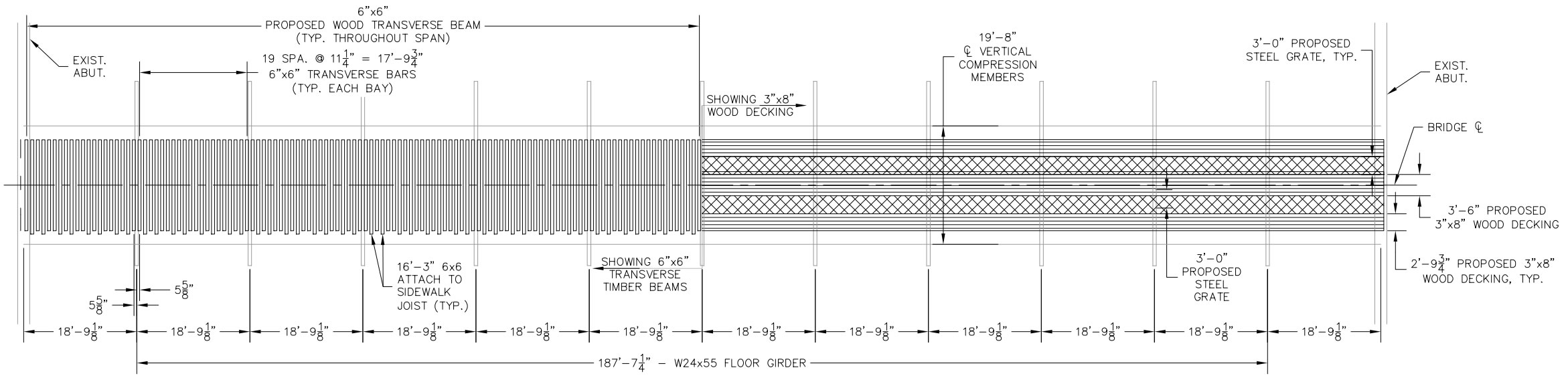

Project Example

Galvanized Steel Grating (Riveted Bar) for Construction Project

Bridge constuction projects:

Galv Steel Riveted Bar Grating for Construction

Supplied with the following information:

- Grate dimensions

- Bar sizes and spacing

- Connection details

- Material type

- Coating

- Surface treatment

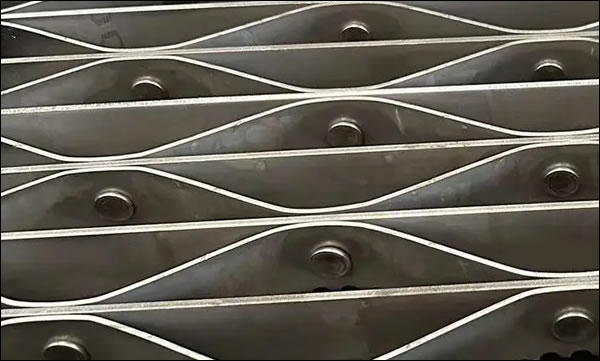

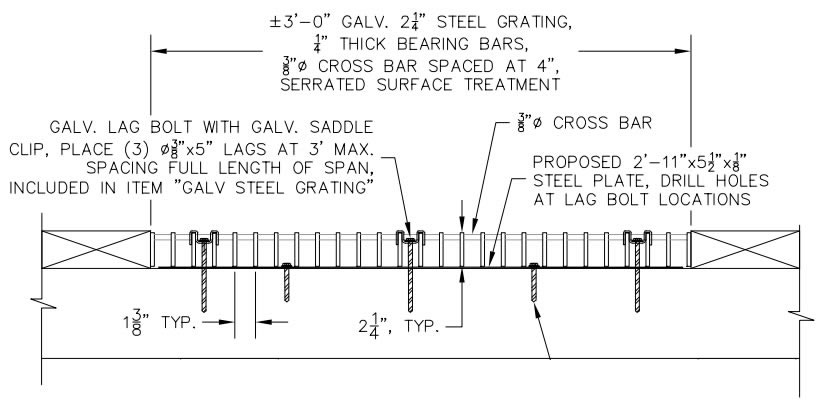

GALVANIZED STEEL GRATING Specification:

Materials.

Structural steel Grade 36 or Grade 50.

Mill reports for steel used in the

fabrication are provided.

Grating 2-1/4” (total depth with serrated edge) x 1/4” bearing bars, spaced at 1-3/8”.

3/8” diameter crossbars spaced at 4”.

Grate width 3 feet.

Section lengths

sized to end at the center of a 6x6 transverse beams, minimum 18’-9” lengths.

Surface treatment: serrated.

Finish: Hot-dipped galvanized.

Connection hardware: Hot-dipped galvanized.

Connection method: by saddle clips and 3/8” diameter by 5” long lag bolts.

Construction:

Place galvanized steel grating full length of the span

accordingly. Assure grating has full bearing on the steel plates

and transverse wood beams. Steel plate hole locations determined according to design plan to allow for saddle clip and lag bolt connections.