We manufacture steel grating, bar gratings, architectural metal grating grilles, and metal steel structures for construction and various industrial uses.

Steel grates offer high strength, light weight, strong anti-corrosion ability, durable, self-cleaning, easy to maintain, good ventilation, allowing good flow of lighting, heat and air, non-slip, and easy to install and remove.

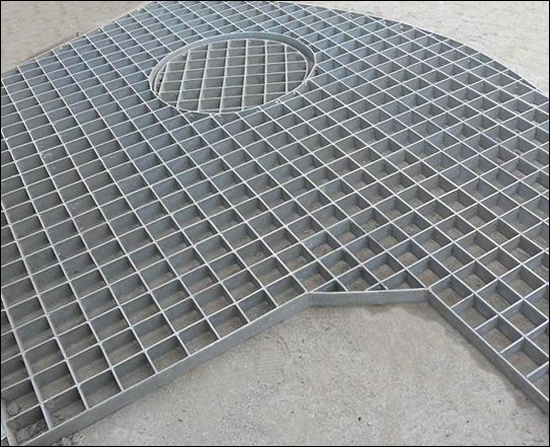

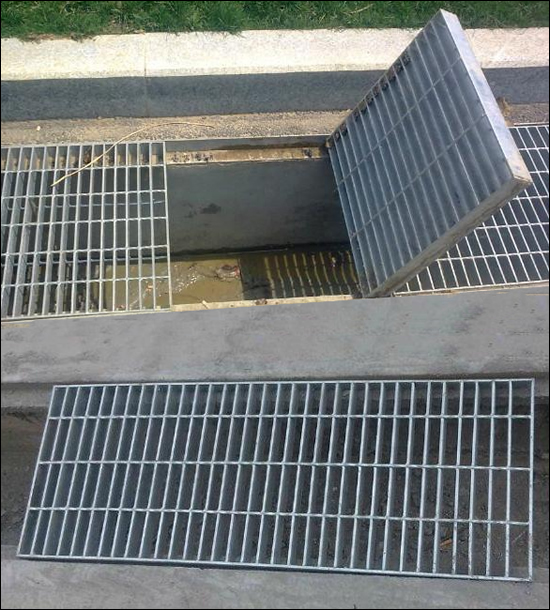

Steel gratings are widely used in various industries, mainly used as ladder treads, handrails, passage floors, railway bridge sideways, platforms walkway and floor, pedestrian grating, drainage ditch covers, manhole covers, road gratings, fencing, ventilation, shading and shielding material in architectural and building and etc.

Steel gratings finishes: Non galvanized steel, black bitumen coated, galvanized or powder coated.

We also supply GRP grating to be used with steel grating for construction, checkered floor plate for grating walkway anti slippery surface.

Steel Grating Processing Types:

Steel grating is constructed of cross bar and bearing bars by way of welding, swage, or pressure locked:

Pressure Welded Grating

Also called electro-forged grating: Bearing bars and cross bars are fused together at intersections through a combination of intense pressure and electric current (resistance welding). This process creates a permanent, strong weld at each intersection.

Swage-Locked Grating

Swage-locked grating is made by inserting of pre-punched cross bars into pre-punched bearing bars. Without the need for welding, the swaging process creates a mechanical connection.

Pressure-Locked Grating

Pressure-locked grating is made by placing cross bars into notches cut in the bearing bars and then applying tremendous hydraulic pressure to lock the bars together. This process creates a strong, rigid connection without welding or swaging, ensures the grating remains flush and provides a clean appearance.

Riveted Grating

Riveted grating is made by riveting cross bars to the bearing bars at intersections, using rivets to form a strong mechanical connection. This process provides exceptional strength and durability, especially for heavy loads and impact resistance.

Dovetail (Interlocking) Grating

Dovetail grating is made by interlocking cross bars into precision-cut slots in the bearing bars, forming a flush, smooth surface. The grating is secured without welding or pressure, providing a clean, aesthetically pleasing appearance.

Expanded Metal Grating

Expanded steel grating is made by stretching and expanding a sheet of metal to form a diamond-shaped grid pattern.

Pultruded Fiberglass Grating

Pultrusion is used to manufacture fiberglass grating by pulling resin-impregnated fiberglass strands through a heated die to form bearing bars. The cross bars are mechanically bonded to the bearing bars. Fiberglass grating is mainly used for corrosion resistance, non-conductivity, and chemical resistance such as chemical plants and offshore platforms.

Types according to Bearing bars: Flat bar grating, serrated grating, I bar grating. Flat steel bar grating is mainly for flooring sidewalk, ditch cover, stair tread, etc.

Types according to the bar materials: Grating can be made into carbon steel, mild carbon steel, galvanised steel, alu or stainless steel.

To order steel grating from us, following information provided will help get a timely efficient response:

Guide to Order Steel Grating

1. Need to specify the material of steel grid plate, flat steel size, surface treatment method.

2. Specify the specific requirements at the edge and opening gap.

3. Provide the size and quantity of the steel grid plate and indicate the direction of the steel grid plate (that is, the span direction, which is usually written behind and followed by "LB" to show the difference).

4. For the convenience of layout design, please provide the following information:

- all relevant dimensions.

- Support beam position, section size, channel steel opening orientation.

- position and size of removable plate, notch.

- The position and size of the fender, front guard.

5. Steel grid plate is usually priced per square meter, according to the YB/T4001-1998 standard area calculation principle, that is, according to the maximum peripheral size, including openings and gaps, see the right picture.

6. Reasonable arrangement of steel grating.

Galvanized Grating Floor Panels for Walkway

Steel Grating For Ditch and Walking Way

Drain grate cover, steel grate drain covers - Trench Cover Grating

Pressure locked flat bar galv grating

Grating Channels, Flooring, Treads-drainage gratings with checker plate nosing

Main Steel Grating Materials:

Open Mesh Grating

Louvre Grating

Galvanized Steel Grating

Press Locked Steel Bar Grating

Bar Type Steel Grating

Plain Type Steel Grating

Forge Welded Steel Grating

Steel Grating Fence

Expanded Steel Grating

Safety Step Bar Grating

Plank Gratings

Checkered Plate for Tread Gratings