Steel Grating Panels Manufactured in Accordance with Standard BS 4592

We manufacture steel gratings following the requirements of international standard and delivering quality products to global customers. BS 4592 standard is UK standard of specifications and guidelines ensuring the safety, durability, and efficiency of steel grating products.

As Suppliers, we can provide the documentation confirming that the steel grating and hot dip galvanized is in compliance with British standard and other international standards required.

BS 4592 steel grating finds extensive use in various infrastructure projects. It is often used in industrial walkways, platforms, and drainage covers, providing safe and stable surfaces in demanding environments.

Products: Steel Grating - BS 4592 Grating Panels

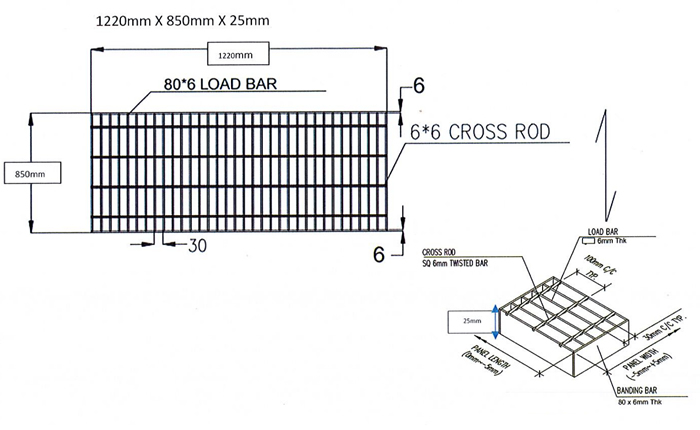

BS 4592 Steel Gratings 1220mm X 850mm X 25mm

Material: Mild Steel S275JR / Q235

Specification:

Load bar: 6mm plain

Cross bar: 6mm twisted square bar

Load bar pitch: 30mm

Cross bbar pitch: 100mm

Surface treatment: Hot dipped Galvanized (Standard = BS729)

Yield Strength: 265 - 300 (N/mm2)

Tensile strength: 400 - 460 mpa

Elongation: 26 - 32 %

Drawing:

Grating panel: 1220mm X 850mm X 25mm

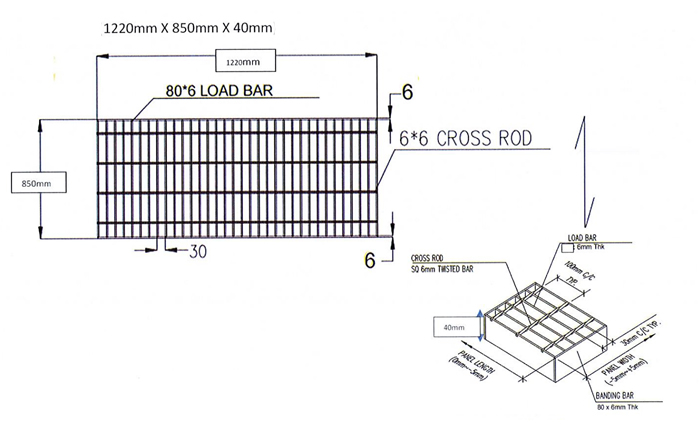

BS4592 Standard Steel Gratings 1220mm X 850mm X 40mm

Material: Mild Steel S275JR / Q235

Specification:

Load bar: 6mm plain

Cross bar: 6mm twisted square bar

Load bar pitch: 30mm

Cross bbar pitch: 100mm

Surface treatment: Hot dipped Galvanized (Standard = BS729)

Yield Strength: 265 - 300 (N/mm2)

Tensile strength: 400 - 460 mpa

Elongation: 26 - 32 %

Drawing:

Grating Panel: 1220mm X 850mm X 40mm

NOTES:

Hot Dip Galvanized in accordance with the requirements of BS 729

Test carried out in accordance with the British Standards and test report indicate the exact British standards specification with which the limits specified in the test report is in compliance.

All spec and test reports in English.

How we control quality:

Material

The raw material used in the manufacture of these steel grating panels is mild steel, specifically S275JR or Q235. These materials are known for their excellent yield strength, which ranges between 265 to 300 N/mm². Furthermore, the tensile strength falls between 400 to 460 MPa, showcasing the material’s ability to withstand significant stress without compromising structural integrity. The elongation percentage stands between 26 to 32%, demonstrating good ductility.

Surface Treatment

To enhance longevity and corrosion resistance, the steel grating undergoes a hot-dip galvanizing process, as prescribed by the BS 729 standard. This treatment ensures the steel grating is well-protected against environmental factors, thus extending its lifespan considerably.

Quality

Adhering to international standards such as BS 4592 and BS 729 in the manufacturing process, our metal gratings meet the the quality, safety, and performance parameters of steel grating products, ensuring they meet the high expectations of global markets.

Steel Grating Drawing

Drawing is an essential step in the manufacturing process, where the detailed schematics of the steel grating are developed. We help design or follow strictly all the specifics, including the dimensions, material grades, and structural attributes, ensuring precision and quality in manufacturing.