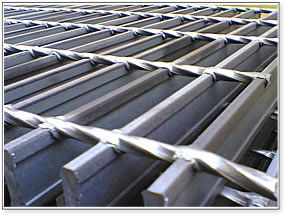

Heavy Duty Deep Flat Bar Grating for Heavy Traffic and Machinery

Heavy Duty Grating is designed with bearing bars thicker and wider than standard bars to handle high load capacities. The heavy duty Deep Flat Bar Grating is used to support heavy loads in high-traffic areas and heavy industrial platforms, such as vehicles, forklifts, or equipment.

Heavy duty steel grating can be banded for additional rigidity or non-banded.

Banding can be added for gratings of following types:

The edges of the grating will be exposed to heavy impacts or traffic;

A clean and finished appearance desired for architectural purposes;

The grating needs additional rigidity to prevent warping or shifting.

Features of Heavy Duty Galvanized Grating:

- Heavy duty design

- Rust and corrosion resistance

- High load capacity

- Open structure

- Slip resistance

Applications:

- For heavy vehicle access points, bridge decking, and highway drainage covers

- For industrial platform walkways, loading docks, and warehouse floors

- For drainage trench covers

- Parking lots

Heavy Duty Galvanized Grating offers good strength, durability and corrosion resistance, mainly used for heavy-duty industrial and infrastructure projects.

Materials:

Carbon steel.

Surface Treatment:

Steel grating untreated, plain black steel;

Galvanized: Hot Dip Galvanizing, corrosion resistant.

Heavy duty steel gratings are economical flooring solutions having excellent load capability and a slip-resistance surface. Heavy duty style grating sheet handles a heavier load than other steel grating, with added angle nosing, it provides additional support along the back edge of the tread to provide superior strength.

Heavy duty steel gratings are economical flooring solutions having excellent load capability and a slip-resistance surface. Heavy duty style grating sheet handles a heavier load than other steel grating, with added angle nosing, it provides additional support along the back edge of the tread to provide superior strength.

Heavy Duty Galvanized Grating for Floor Grating

Type: Deep Flat Bar Grating

Common specifications:

Load bearing bars are produced from steel of following equivalent standards: AS3679 Grade 250, BS4360 Grade 43A and ASTM A36 or equivalent.

Serrated surface (serrated bar), banded with the same size flat bar (end banding type), hot dip galvanized.

The minimum average hot dip galvanized coating required by standards AS1650, BS729 and ASTM A123 is 610gms/sq metre (the minimum average thickness of galvanized coating must be 87.14 micron).

Width: 600 mm / 900 mm / 1200mm

Length: 1000mm - 1800 mm

Heavy Duty Galvanised Grating - Banding Type

Heavy Duty Banding Galvanised Grating is steel grating specifically designed to withstand heavy loads, reinforced with banding for additional strength and stability.

Heavy Duty Banding Galvanised Grating Popular Size: 750mm x 640mm x 75mm thick

Installation of Heavy Duty Bar Grating Floors:

Installation of heavy steel grating can be welding or folder installation. Welding fixed for the permanent position does not require demolition, such as equipment around the platform. Installation with the use of the installation folder does not undermine the zinc layer and the demolition of the characteristics of convenience.

Weld fixing: usually at a flat 2 flat steel welding, weld length of not less than 20mm, not less than the high welding 3mm, the use of plane angle weld; if the grating or the span of particularly large particularly when the load above the need to strengthen the joints.

Installation folder is used for a variety of grating specifications.

32x5mm Serrated Steel Grating Walkway Platform-100X5mm Cast Iron Heavy Duty Steel Grating

HDG Heavy Duty Galvanised Steel Grating

Banding used on the edges of grating panels for industrial walkways, platforms, stair treads, drainage systems, and other structural installations.