Steel Grating Parameters

Steel grating is a metal structure with welding or pressure locked. We mainly introduce processing and major parameters of the two types of steel grating (welded and locked).

Steel Grating Structure and Processing Technology:

Steel grating is a kind of square opening steel structure welded or plugged with flat-rolled steel and cross bars lined and crossed with certain spacing. Steel grating has good ventilation, lighting, cooling, slip-proof properties. Mainly used to make steel structure platform plates, steel ladder treads, steel grating fence and drain covers and so on.

Steel grating can be divided into two major types according to processing methods: pressure welding and pressure locked.

Welded steel grating technical parameters:

1. Material:

① Flat-rolled steel: high quality low carbon steel, stainless steel, aluminum alloy steel.

② Cross Bar: Q235A or optional 304 stainless steel twisted steel, square steel, round steel, flat steel.

2. Flat Bar Surface Shape: flat, serrated, I -shaped, toothed.

3. Flat Bar Specification:

① Plane Flat Bar Specification:

a Thickness: commonly 3mm and 5mm;

b Height: commonly 25mm, 30mm, 32mm, 40mm, 45mm, 50mm, 60mm and so on.

① I -shaped Flat Bar Specification:

a, Thickness of both ends: 5mm;

b, Thickness of the center: 3mm;

c, Height: commonly 25mm, 32mm, 38mm, 44mm, 50mm and so on

4. Flat Bar Spacing: Two adjacent center bearing bar distance , commonly three sizes: 30mm, 40mm, 60mm. Dense steel grating spacing is less than 25mm. Steel grating is mainly used for demanding applications.

5. Cross Bar Specification: common specifications: 5 × 5,6 × 6,8 × 8mm.

6. Cross Bar Spacing: Center distance between two adjacent bar is typically 50mm, 100mm

7. Length of Steel Grating Panel:. General steel grating length ≥ 800mm. Trench cover for large span platform has a length of 3000-10000mm.

8. Surface Treatment: Electro-galvanized, hot galvanized , painting, dipped rust-proof oil. These treatment can play a role in preventing oxidation.

9. Steel Grating Shape: Square steel grating , rectangular steel grating , steel grating with round edging , V- groove decking , profiled steel grating , fan-shaped steel grating combined into hollow circular plate, semicircular steel grating , special shaped steel lattice panels, profiled steel grating

10. Packaging Methods:

① Strap Packaging: Generally for relatively common shape steel grating .

② Pallet Packaging: General packing for export.

③ Screw Rod Fixation: Using four screws through the steel grating aperture, locking screw packaging method .

Bundled neatly packaged steel grates with a packing strap, steel grating packed into pallet, steel grating packed with screw locking rod, steel grating packed with screw locking rod.

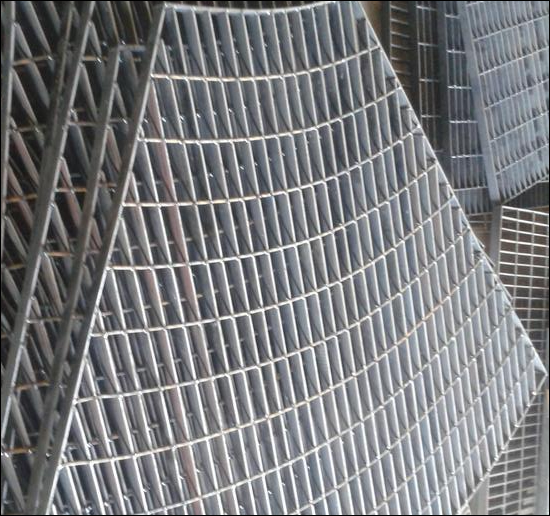

Photo Illustrations:

Hot Dip Galvanized Steel Welded Grating with serrated bearing bars

Pressure locked steel grating technical parameters:

The crossing bar of standard pressure lock steel grating bar is usually 20 × 5mm flat steel ( or other specifications ) , pushed by strong pressure into the bearing flat steel. The jointing spots between flat steel bars are locked by the pressing force yielded through deformation. The steel bar can be made of ordinary steel, aluminum or stainless steel.

Pressure Locked Steel Grating Type: Total four types: ordinary type, the integral type, shade -type , heavy-duty.

1. Common Type:

① After bearing flat steel bar grooving, the crossing flat steel bar pressure locked.

② Ordinary steel grating maximum working height: 100mm.

③ Steel grating length is usually less than 2000mm.

2. Integral Type:

① Flat bearing flat steel bar and crossing bars have the same height, grooving depth is 1/2 of that of bearing flat bar.

② Steel grating panel height: max. 100mm.

③ Steel grating panel length is usually less than 2000mm.

3. Shading Type:

① Flat bearing bar grooving at 30°or 45°, then pressure locked.

② Other spacing and specifications according to different needs.

③ Grating panel height is less than 100mm.

4. Heavy Loading Type:

② The bearing flat steel bar and the crossing bar pressure locked under pressure of 1200 tons.

② Suitable for big span heavy loading applications.

Photo Illustration:

Grating Channels Hot Dipped Galvanized Mild Steel, Grid Safety Mats