Hot Dipped Galvanized Steel Grating - HDG Floor Grating-Gangway and Ladder Safety Grating

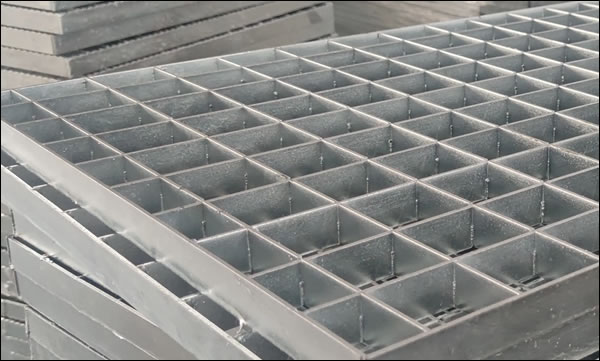

Hot Dipped Galvanized Grating ( simplified as HDG Grating) is a versatile bar grating flooring material made of quality carbon steel in accordance with Chinese standard, American Standard, Australia or British Standard. The hot dipped galvanizing for the steel plate surface is processed according to standard: China GB/T13912-92 / ASTM (A123) / BS729. The thick zinc coating gives more protection and enables the grating floors excellent corrosion resistance for on-shore and off-shore elements. Hot dipped galvanized grating has bright metal aesthetic appearance and a light structure easy for loading and installation.

Features

Good anti-corrosion capacity;

Shiny surface appearance;

Ventilation;

Heat, explosion-proof;

Others.

Qindelin hot dipped galvanized steel grating meets the following standards:

Steel material we use meets the Standard of China GB700-88 / ASTM (A36) / BS4306 (43A).

HDG Grating production meets one of the following:

China YB/T4001-1998

America ANSI/NAAMM (MBG531-88)

Britain BS4592-1987

Australia AS1657-1992

Applications

Hot dipped galvanized grating with excellent corrosion resistance makes good choice for outdoor off shore industrial gangway flooring panels and ladders. Common sizes for hot dipped safety grate is 30 × 3mm thick load bearing bars with a pitch of 30mm and traverse bars at 50mm or 100mm.

HDG Gratings with Steps and Assembly Accessories

Gratings hot dip galvanized

Load bearing bars: 30 mm x 3 mm, mesh

30x50 mm center to center.

Weight of removable panels less than 50 kg each panel.

With steps for the grating

With Staples, accessories necessary for the assembly of the grating.

Types:

Hot Dipped Galvanized Steel Gratings (Straight)

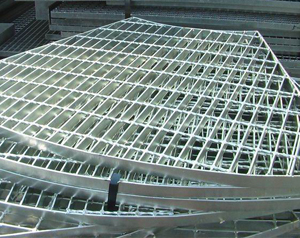

Hot Dipped Galvanized Polygonal Steel Gratings

Straight and polygonal grating panels with or without holes, including loading on the truck, the toe plate extension for floor opening for pipes, columns, equipment frames/brackets/skirt ring base, according to construction project requirement.

Including mounting and fixing devices.

Four fixing device for each panels. Fixing devices type vary to meet construction standards.

Bound strips provided around all panels.

Bearing bars: Serrated type.

Gratings cut to measure

Gratings finish: Hot dip galvanized.

Weight of removable panels : less than 50 kg each panel.

Grating panels includes the holes from 300 mm (included) and over.

Hot Dip Galvanized Steel Grating

Grating HDG - Steel structural materials for replacing scaffold by maintenance platform

GRATING MATERIALS for Work and Maintenance Platforms

| HDG GRATING FOR MAINTENANCE PLATFORMS |

| |

CLASS - GRADE |

DESCRIPTION |

| |

ASTM A36 |

CS Plate 3/8" (10 mm) THK. 4ft x 8 ft |

| |

ASTM A36 |

CS Plate 5/8" (15 mm) THK. 4ft x 8 ft |

| |

ASTM A36 |

L65x65x6, HDG, 20' EA |

| |

ASTM A36 |

Flat Bar 4"x1/4" HDG, 20' EA |

| |

ASTM A36 |

Flat Bar 1"x1/4" HDG, 20' EA |

| |

ASTM A36 |

Flat Bar 2"x1/2" HDG, 20' EA |

| |

ASTM A36 |

Flat Bar 2"x1/4" HDG, 20' EA |

| |

ASTM A36 |

Carbon Steel ROD 3/4" RB20, 20' EA |

| |

ASTM A325 |

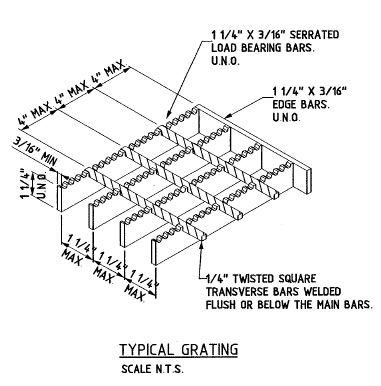

Grating HDG, 1.1/4" (32 mm.) x 3/16" THK (5 mm)Load bearing bars - Serrated. W/ 1/4" (6 mm) Twisted square transverse bars welded flush or below the main bars. 3ft x 20 ft EA. |

| |

ASTM A36 |

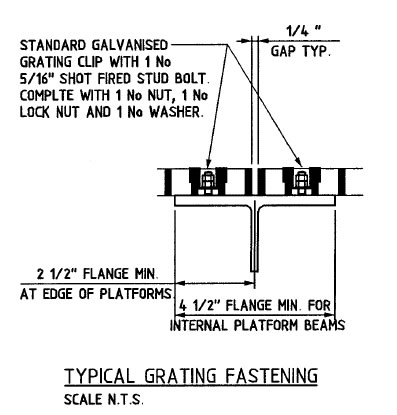

Grating Clamps comprising of: - Saddle clip - Pressed clamp plate - M 8 x70 1mn Bolt and Nut - HDG. |

| |

ASTM A325 |

Bolt ASTM A-325, W/Heavy hex nut, DIA. 3/4" (20 mm.) Length = 2.1/2" (65 mm.) HDG |

| |

ASTM A325 |

Bolt ASTM A-325, W/Heavy hex nut, DIA. 1/2" (12 mm.) Length = 2" (50 mm.) HDG (for handrail) |

| |

U8.8 |

Chemical Bolt DIA. 3/4" (20 mm.) Length= 14 3/16" (360 mm.) with hilti RE500 V3 (HAS-U8.8 M20 (GALV.) |

| |

EPOXY |

HIT-RE 500 V3 EPOXY ANCHOR (500ML) |

Gratings comply with following TYPICAL GRATING drawing:

Clamps comply with following TYPICAL GRATING FASTENING drawing:

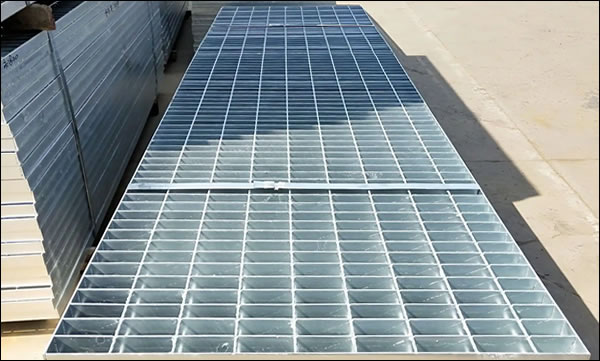

HDG Steel Grating

Material: ASTM A36

Sheet: 1m x 6m

Supplied with fixing clips for HDG steel grating

Finish: HDG zinc coated.

Floor Grating HDG (Hot Dip Galvanized)

Process type: Press locked grating

Floor Loading Capacity

a. Main Aisle and Center Aisle = 500kg/m2

b. Picking Aisle = 300kg/m2

c. Flooring Materials for all area – floor grating 22x66

Specifications:

Press locked gratings, mesh 66x22, bearing bar 35x1.8, grade S235, hot dip galvanized finish

Grating capacity: capable to carry a UDL of 350kg/sqm respectively a man load of 100kg or a wheel load of 40kg on 50x50mm imprint over a clear unsupported span of 1100mm.

Press locked gratings, mesh 66x22, bearing bar 35x1.8, grade S235, hot dip galvanized finish

Grating capacity: capable to carry a UDL of 500kg/sqm respectively a man load of 100kg or a wheel load of 40kg on 50x50mm imprint over a clear unsupported span of 1100mm.

Press locked gratings, mesh 66x22, bearing bar 30x2, grade S235, hot dip galvanized finish

Grating capacity: capable to carry a UDL of 500kg/sqm respectively a man load of 100kg or a wheel load of 55kg on 50x50mm imprint over a clear unsupported span of 700mm.

Samples Illustration:

Hot Dipped Galvanized Gangway Tower Grating

Polygonal Grates made of carbon steel with heavy zinc coating, for sea-shore gangways structure.

HDG Galvanized steel plate safety grating ladder rung for step /Metal Building Construction Materials Steel Grating