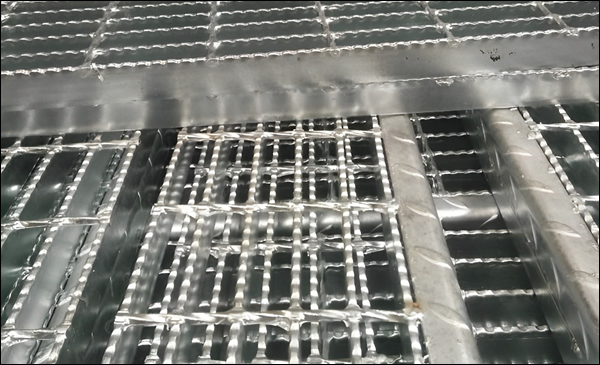

HDG Steel Serrated Grating for Bridge Platforms

We supply HDG (Hot Dipped Galvanized) steel serrated grating for industrial platforms with commitment to quality and safety of the construction projects. Following is reference size for Saudi Arabia Project. Various specifications available for specific requirements.

HDG Steel Serrated Grating for Platforms

Size:3000 × 1000 × 30 mm HDG galvanized steel serrated grating

Bearing Bar width: 30 mm.

Thickness/width of banding bar: 5.0 mm.

Twisted bar thickness: 8.0 mm.

Bearing bar centers pitch: 25 mm.

Cross bar centers pitch: 100-103 mm.

Closed end.

Steel material: ASTM A36

MAx Allowed Tolerance: +0.04% -0.04%.

Surface treatment/ Coating: HDG,Hot dip galvanised (over 500gm/m2).

Material certificate to ASTM

Structure and Features / Why Choose HDG Steel Serrated Grating for Platforms?

- Size: Available in standard and customized sizes tailored to meet the diverse needs of various projects.

- Bearing Bar offers substantial support and stability.

- Banding Bar Thickness varies, providing robustness to the structure.

- Twisted Bar adds to the dimensional strength of the grating panels.

- Bar Centers Pitch: The bearing bar centers have a pitch of 25 mm, while the cross-bar centers range between 100-103 mm, allowing for optimal load distribution and safety. Various pitch design available upon specific requirement of projects.

- End Type: The grating is designed with a closed end, enhancing its structural integrity and safety features.

- Tolerance: It adheres to strict tolerance levels, with a maximum allowed variation of +0.04% to -0.04%, ensuring precision and quality.

Choice Material

The material of choice for HDG serrated grating is ASTM A36 steel, known for its excellent strength and mechanical properties.

Surface Treatment

HDG (Hot Dipped Galvanized) Steel Serrated Grating is known for its durability and versatility, can be used as a prime choice for numerous applications in the infrastructure and construction industry. The thick Hot dipped zinc coating of over 500gm/m2 not only ensures high durability but also long-term resilience against various environmental conditions, making it a reliable choice for a range of applications.

Uses

HDG steel serrated grating finds widespread applications owing to its strength and durability. It is extensively used in industrial platforms, walkways, drainage covers, and stair treads. Its serrated surface offers excellent slip-resistance, making it a safe option for environments prone to moisture and lubricants. Moreover, the hot dipped galvanized coating increases corrosion resistance and prolong the life span of the infrastructure where it is applied.

Standard

HDG steel serrated grating for platforms complies with the standards of material ASTM, guaranteeing high quality and reliability. The material certificate to ASTM attests to the product meeting the stringent requirements, making it a globally accepted choice for numerous infrastructural projects.