Eurocodes Metal Grating Panels for Floorings and Steps in Vehicular and Pedestrian Areas

We supply metal bar grating of quality compliance to Eurocodes for industrial flooring and maintenance walk ways.

Grating Materials for Structural Steel Constructions

EN10025:Non-alloy structural steels

- EN 10219-2:Cold formed welded structural hollow sections of non-alloy and fine grain steels - Part 2:Tolerances, dimensions and sectional properties.

- EN 10210-2:Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-alloy structural steels

- EN ISO 1460:1994 Metallic coatings. Hot dip galvanized coatings on ferrous materials. Gravimetric determination of the mass per unit area.

- DIN 18203:Tolerances for buildings - Part 2: Prefabricated steel components.

Eurocodes Metal Grating Products

Specification and standard

QUALITY:

Metal Bar Grating Standards: Comply with UNI 11002-1:2009 - Metal grating panels for floorings and steps - Part 1: Terminology, tolerances, requirements and test methods for panels for use in floorings in vehicular and pedestrian areas

Formed-metal plank gratings for maintenance walk ways /steel stairs steps

Clips and anchorage devices for gratings

Entryway systems foot grilles

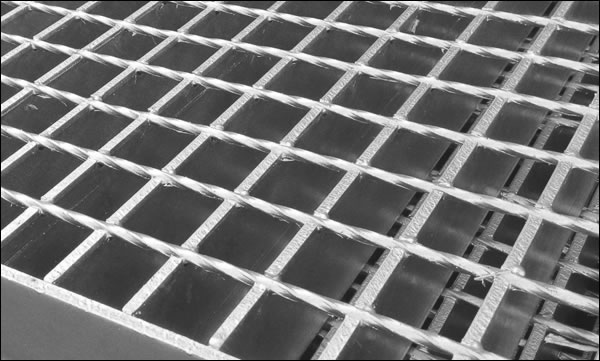

Metal Bar Gratings

30mm thick

Metal Bar Gratings 50mm thick

Supplied with clamps

Grating Design:

Structural Performance: Gratings to withstand the effects of gravity loads, compliance of the gratings according to the Eurocodes.

Drawing

Structure Detail

FLOOR TYPE

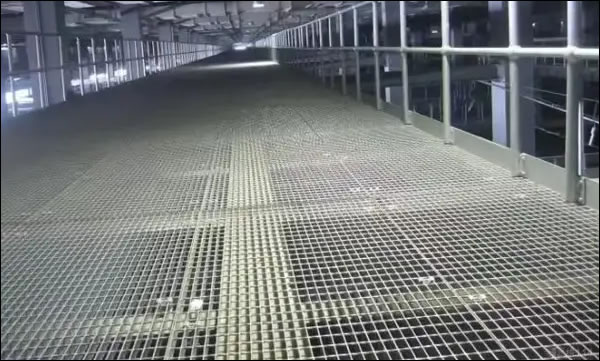

Grating Installation

- A. Inspect areas to receive Metal Grating for obstacles. Notify the Engineer of conditions that would

adversely affect the installation or subsequent utilization of the areas. Do not proceed with

installation until unsatisfactory conditions are corrected.

- B. Install Metal Grating according to construction plan.

- C. Position Grating sections flat and square or L sections supporting structure.

- D. Keep sections at least 5 mm away from vertical steel sections and 10 mm from concrete walls.

- E. Allow clearance at joints between sections of maximum 5 mm at side channels and maximum at

ends.

- F. Band random cut ends and diagonal or circular cut exposed edges with a minimum 3 mm thick

bar welded at contact points.

- G. Join abutting walkway sections with splice plates; bolted or welded per specified.